Battery of Capacitor

Electrical energy accounts for a significant proportion of operating costs in industry, and its inefficient use can lead to significant additional costs. To improve energy efficiency, installing capacitor banks is a sensible solution. We can offer you all our expertise and experience to optimise energy management in an industrial installation. Below is our approach to sizing and installing capacitor banks in an establishment or industry.

1.Pre-evaluation of the electrical system

Before we start installing capacitor banks, we carry out a thorough assessment of the industry’s electrical system. This identifies areas with a low power factor, indicating where adding capacitors would be most beneficial.

2.Design of the Capacitor Bank System

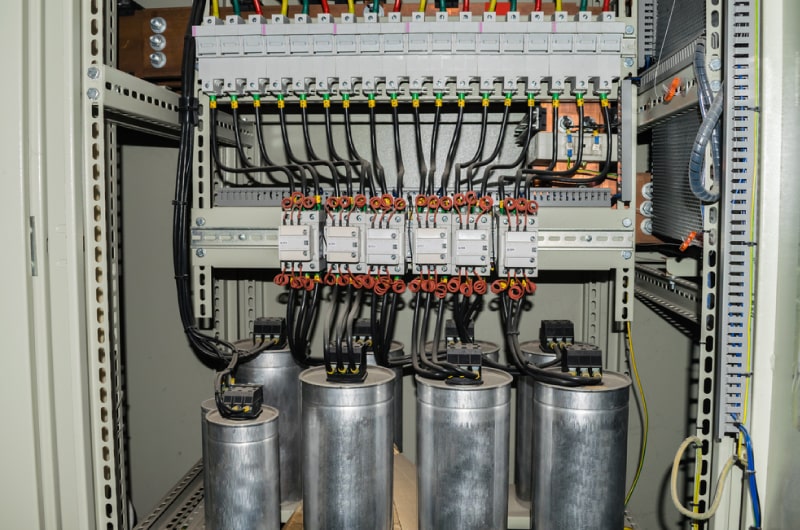

The design of the capacitor bank system must be adapted to the specific needs of the industry in question. It is essential to take into account the variability of the electrical load and to size the capacitor banks accordingly. The design should also incorporate automatic control devices to adjust the compensation in real time, thus guaranteeing optimum performance. It is also crucial to analyse the rate of harmonics in the electrical network and provide anti-harmonic filters if necessary to protect our equipment against any risk of damage. In this case, we’re talking about an automatic anti-harmonic capacitor bank (or one with an inductance).

3.choice of capacitor banks

The market offers a variety of capacitor banks, each adapted to specific applications. It’s crucial to select quality capacitors that meet industry standards and offer a long service life. Also consider characteristics such as rated voltage, reactive power and frequency to ensure perfect compatibility with the existing electrical network.

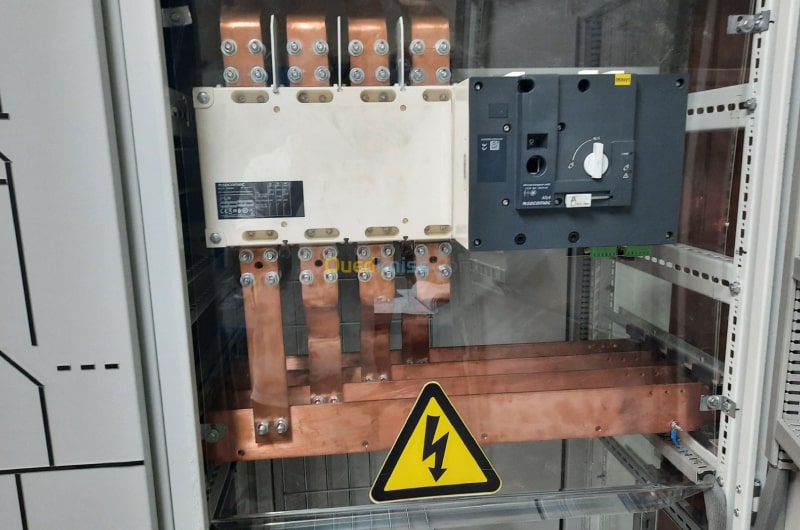

4.Physical installation of capacitor banks

Once the design has been finalised and the capacitor banks selected, the physical installation can begin. This process involves mounting the capacitors in dedicated electrical cabinets, connecting them to the appropriate circuits, and fitting the necessary safety devices.

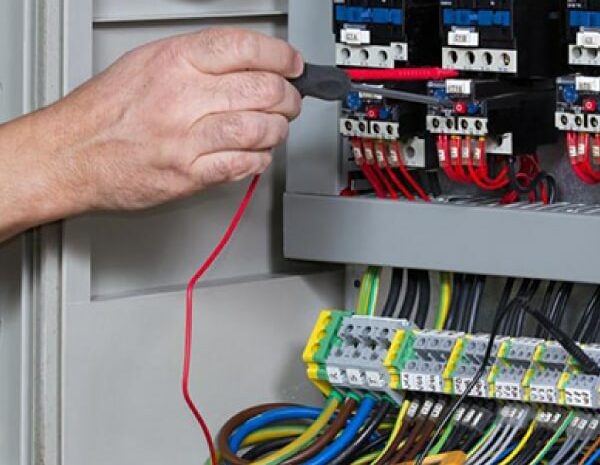

5.commissioning and settings

The commissioning of capacitor banks requires special attention. Our qualified engineers supervise this stage to ensure that the capacitors operate correctly and that the expected reactive power compensation is achieved. Precise adjustments must be made to guarantee optimum performance and avoid any risk of overcompensation.

6 Staff training and ongoing maintenance

Once the system is up and running, it is essential to train staff in its operation, safety procedures and signs of possible malfunction. Regular maintenance is also crucial to ensure the system’s longevity. Periodic inspections, performance tests and the replacement of faulty components should be part of a preventive maintenance plan.

Installing capacitor banks in an industry represents a strategic investment to improve energy efficiency. By following these steps, from initial assessment to ongoing maintenance, companies can not only reduce their energy costs, but also contribute to environmental sustainability. The transition to more efficient electrical energy management is an important step towards a more responsible and profitable industrial future.

Save your

Electrical installation

Our Projects recently

EL MOURADI

El Ahmadi residence

El Ahmadi residence

Résidence El Ahmadi is a high-standard commercial and residential development

WEWIRE (Coroplast)

WEWIRE (Coroplast)

Construction of a WeWire factory in Ennfidha and Hamamet, electrical lot.

Thomas Tunisie Plastec

Hotel the Residence

TERIAK

Our Partners